In the last article, Elaried talked about three kinds of workpiece measurement methods, namely direct measurement and indirect measurement, absolute measurement and relative measurement, contact measurement and non-contact measurement. Do you think that the workpiece measurement methods are these three? Of course not! In this article, we will introduce the remaining 3 workpiece measurement methods.

In the last article, Millired talked about it for you3Kind of

Job measurementThe methods include direct measurement and indirect measurement, absolute measurement and relative measurement, contact measurement and non-contact measurement. You think that's how you measure a workpiece3What kind of seed? Of course not! Here, Millired will provide you with the rest3Kind of

Job measurementMethod.

First, according to the number of measurement parameters, it is divided into single measurement and comprehensive measurement.

Individual measurement:Each parameter of the part under test is measured separately.

Comprehensive measurement:Measure the comprehensive index that reflects the relevant parameters of the part. For example, when using a tool microscope to measure the thread, the actual diameter of the thread, the half Angle error of the tooth profile and the cumulative error of the pitch can be measured respectively.

Comprehensive measurement is generally more efficient, more reliable to ensure the interchangeability of parts, and is often used for the inspection of finished parts. Single measurement can determine the error of each parameter respectively, which is generally used for process analysis, process inspection and measurement of specified parameters.

Second, according to the role of measurement in the processing process, it is divided into active measurement and passive measurement.

Active measurement:The workpiece is measured during the machining process, and the results are directly used to control the machining process of the parts, so as to prevent the production of waste products in time.

Passive measurement:Measurement of the workpiece after machining. This kind of measurement can only determine whether the workpiece is qualified, only to find and remove the waste.

Third, according to the state of the measured part in the measurement process, it is divided into static measurement and dynamic measurement.

Static measurement:Measurement is relatively static, such as a micrometer measurement.

Dynamic measurement:During the measurement, the measured surface and the measuring head move relative to each other in the simulated working state.

The dynamic measurement method can reflect the situation of parts close to the use state, which is the development direction of measurement technology.

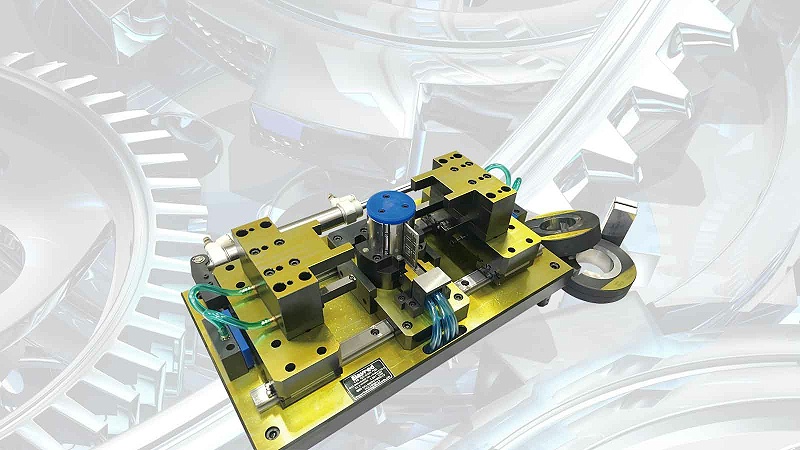

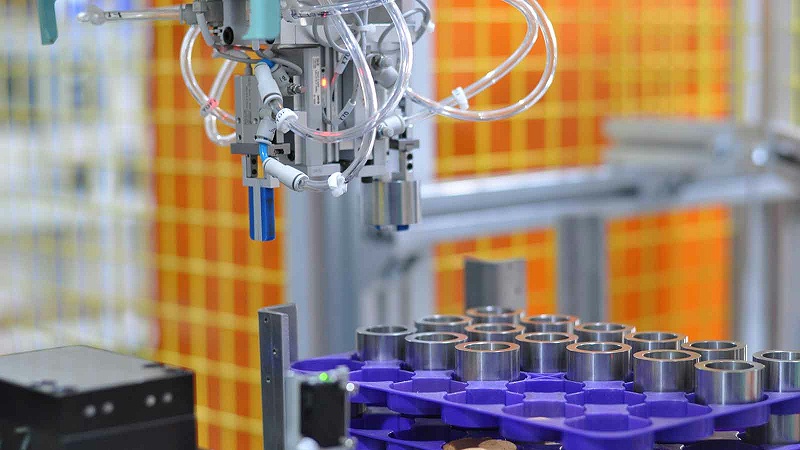

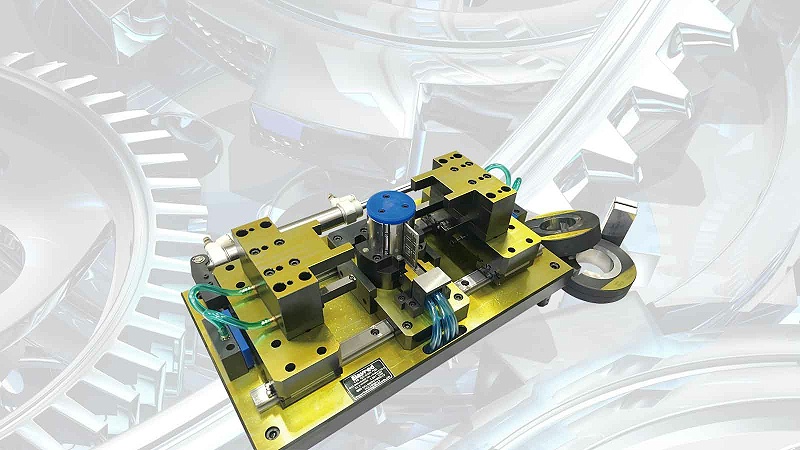

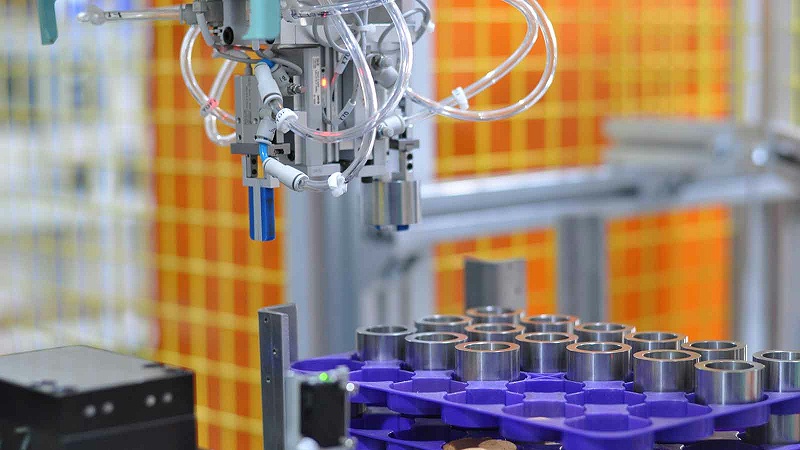

Yileride focuses on precision parts size pneumatic measurement, as a national high-tech enterprise and private science and technology enterprises in Jiangsu Province, has12Human technology research and development team, research and development personnel have participated in the United States Group, Gree, Mitsubishi, Panasonic and other companies of automatic measuring machine research and development, the company's annual research and development investment200Million, research and development of new products is not less than15A, if you're right

Job measurementInterested or want to know more details, please click on our online customer service for consultation, or directly call the national unified service hotline

400-682-7787. We look forward to your call!