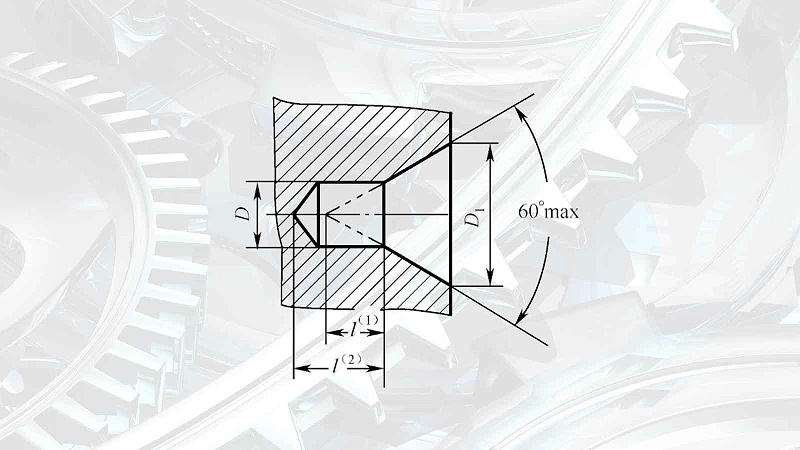

AThe main disadvantage of the center hole is that the hole is easy to be damaged, resulting in poor contact between the center hole and the top cone, which causes the runout of the workpiece and affects the accuracy of the workpiece.

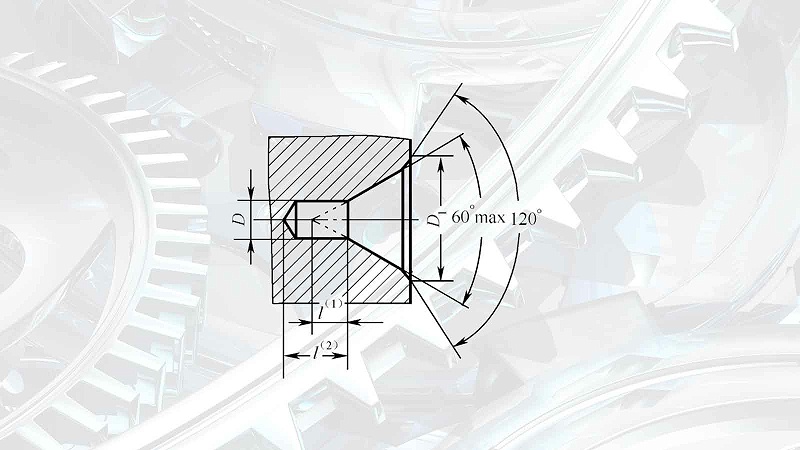

BThe center hole is mainly used for the case that the center hole should continue to be used after the parts are processed, such as the center hole on the tool such as the reamer.

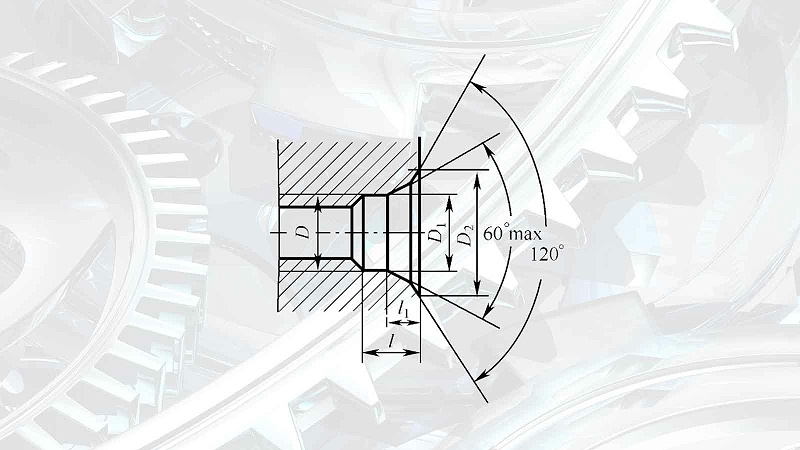

CThe main feature of the center hole is that there is a small section of threaded holes on it, as shown in the figure. It is used when the workpiece is required to be fixed on the shaft, such as the center hole above the taper shank end mill used on the milling machine, the taper shank keyway mill and its connecting sleeveCType center hole.

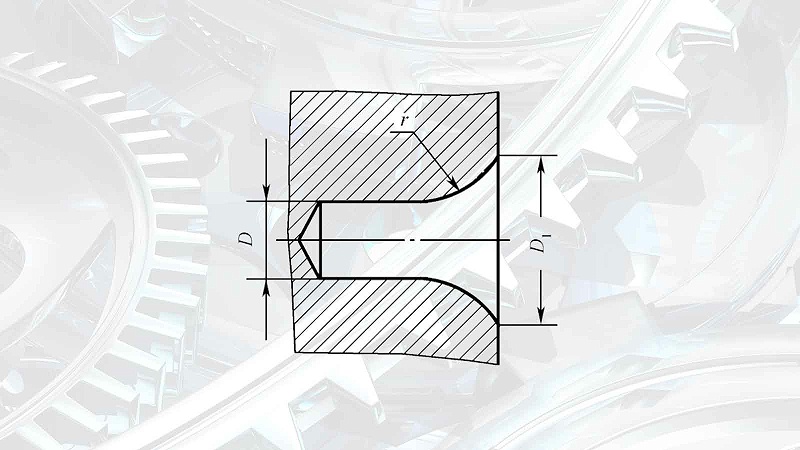

RType center hole is also called circular arc center hole, because of its connection with60°The contact of the top, theoretically speaking, is line contact, so the friction generated when the center and the center hole are relatively rotating is small, the rotation is light, and the processing accuracy of the center hole is high. Therefore, the positioning accuracy requirements are moreShaft partsAnd round broach and other precision tools, should be selectedRType center hole.

Model:E-MA4; Measuring range:±25μm,±50μm; Resolution:0.1/0.2/0.5/1.0; Total error:2%; Number of channels:Single; Measuring function:MXMNMNIAN-AMIN2

Model:E-MC5; Measuring range:±25μm,±50μm; Resolution:0.1/0.2/0.5/1.0; Total error:≤0.3μm; Number of channels:Single; Measuring function:MXMNMNIAN-AMIN2

Display screen:7Inch; A/E:EA-2; Accuracy:≤0.3μm Resolution:0.1/0.2/0.5/1.0 Unit:μm/mm/inch