Pneumatic measurement is to use the change of air pressure to detect the size and form error of the part. The following advantages of using a gas gauge to detect the workpiece:

Pneumatic measurement is to use the change of air pressure to detect the size and form error of the part.

The following advantages of using a gas gauge to detect the workpiece:

1Good versatility.The air momentum meter can be used to detect the various dimensions of the parts and the form and position errors such as flatness, roundness, verticality, taper and straightness.

2Fast speed.It takes only a few seconds to measure a part.

3, high precision.Repeatability of pneumatic measurement can be achieved1〃(25.4mmOne millionth of that.

4Good consistency.Different inspectors can obtain consistent measurement results.

5Easy to use.The measurement procedure is simple and easy to understand, and the operator does not need to undergo professional training.

6, non-contact measurement.It will not damage the part under test and can measure thin-walled parts without causing thin-wall deformation.

7, self-cleaning function.The airflow used for measurement removes debris or coolant from the workpiece.

8Long service life.The air gauge has no moving parts, will not wear, not easy to damage.

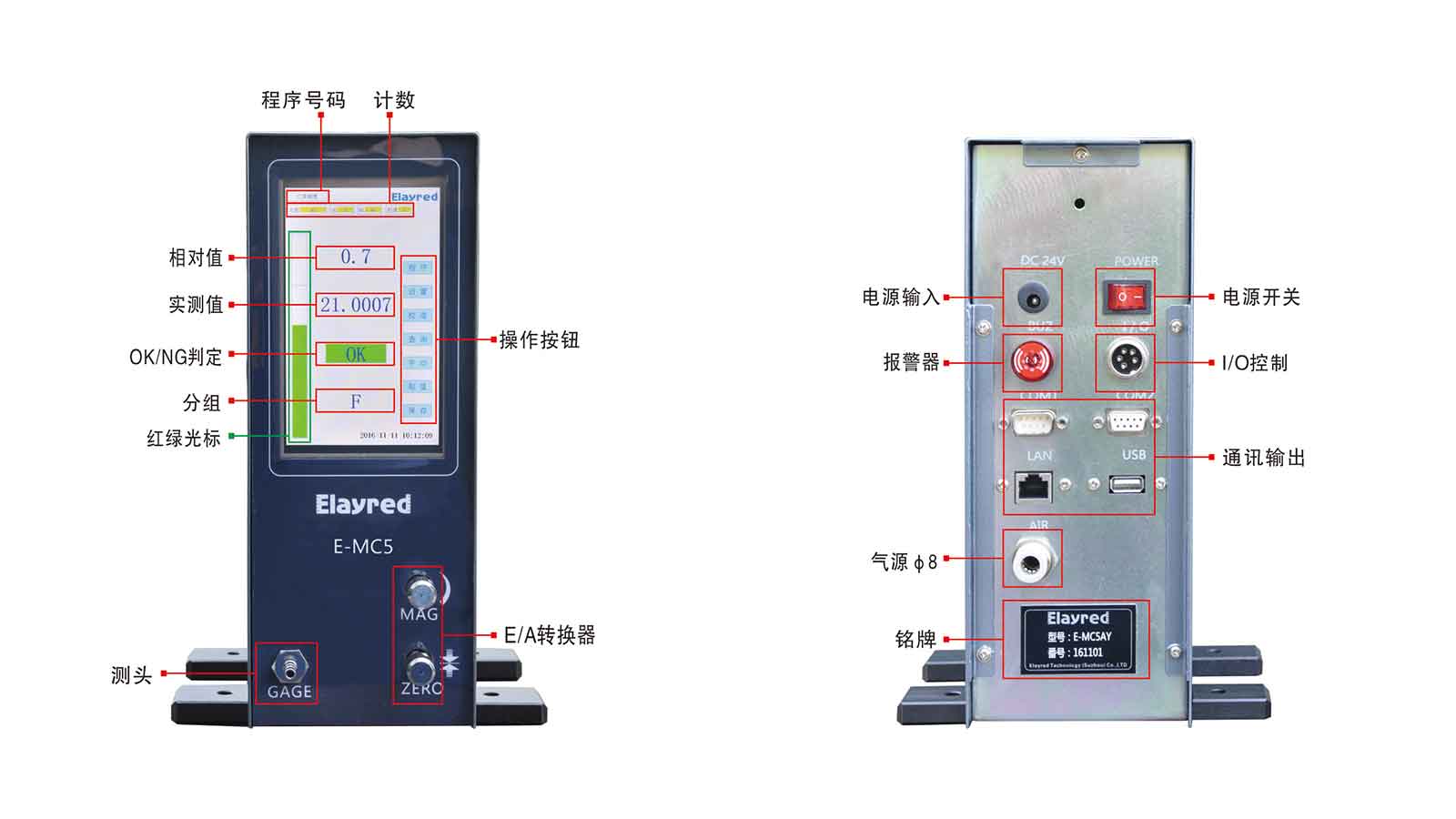

Yileride focus on micro precision, research and development and production of digital display gas momentum meter, a variety of models, quality assurance, factory direct sales, price concessions.

If you are

Digital display gas momentum meter Interested or want to know more details, please click on our online customer service for consultation, or directly call the national unified service hotline

400-682-7787. We look forward to hearing from you!