The gas meter can be seamlessly integrated with the automated production line to1SThe left and right detection beat (excluding loading and unloading time) detects various parameters of the workpiece. For example, the customized measuring equipment developed and produced by Eleride:Piston automatic measuring machineFor air conditioning rotary compressor piston, ring, roller automatic measurement and sorting, mainly measuring the inner diameter, roundness, cylindricity, perpendicularity; Outer diameter, roundness, cylindricity, perpendicularity, inner and outer concentricity, wall thickness, height, parallelism and other parameters, accuracy≤0.0005mm, beat5~8seconds/A piece.

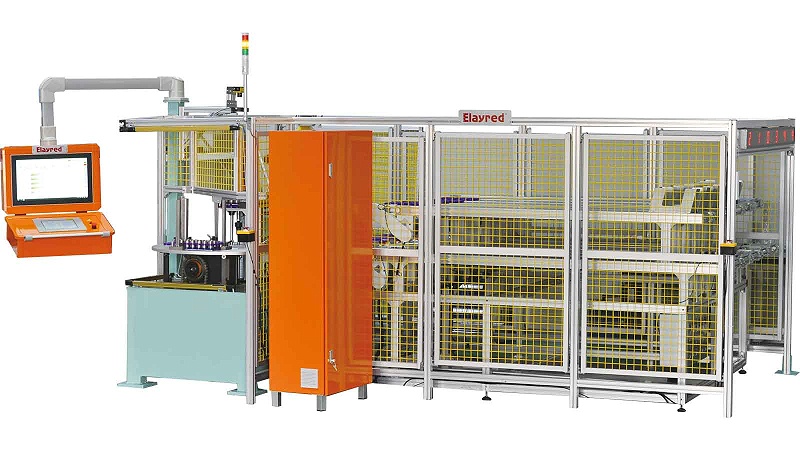

Automated production line is a system that can realize the automation of the product production process, using a set of machines and equipment that can automatically process, detect, sort, assemble, test, package, load and unload, and transport to achieve the production of products, which not only improves the work efficiency, but also reduces the production cost and improves the processing quality.

Model:E-MA4; Measuring range:±25μm,±50μm; Resolution:0.1/0.2/0.5/1.0; Total error:2%; Number of channels:Single; Measuring function:MXMNMNIAN-AMIN2

Model:E-MC5; Measuring range:±25μm,±50μm; Resolution:0.1/0.2/0.5/1.0; Total error:≤0.3μm; Number of channels:Single; Measuring function:MXMNMNIAN-AMIN2

Display screen:7Inch; A/E:EA-2; Accuracy:≤0.3μm Resolution:0.1/0.2/0.5/1.0 Unit:μm/mm/inch