Since there is processing accuracy in the precision manufacturing process, there will be processing errors, and can the processing errors be avoided? Don't worry, let Millired explain it to you!

Since there is processing accuracy in the precision manufacturing process, there will be processing errors, and can the processing errors be avoided? Don't worry. JustBillion lerideLet me explain it to you!

Machining error refers to the deviation of the actual geometric parameters (size, shape and position) of the workpiece to the design geometric parameters. In the production practice, the process factors that affect the machining accuracy are intricate. Any processing and measurement will inevitably have errors, the so-called high precision, but the error is small. For some machining errors, we can not only use single factor analysis to solve them, but need to use probability statistical method to conduct comprehensive analysis, find out the causes of machining errors, and eliminate them.

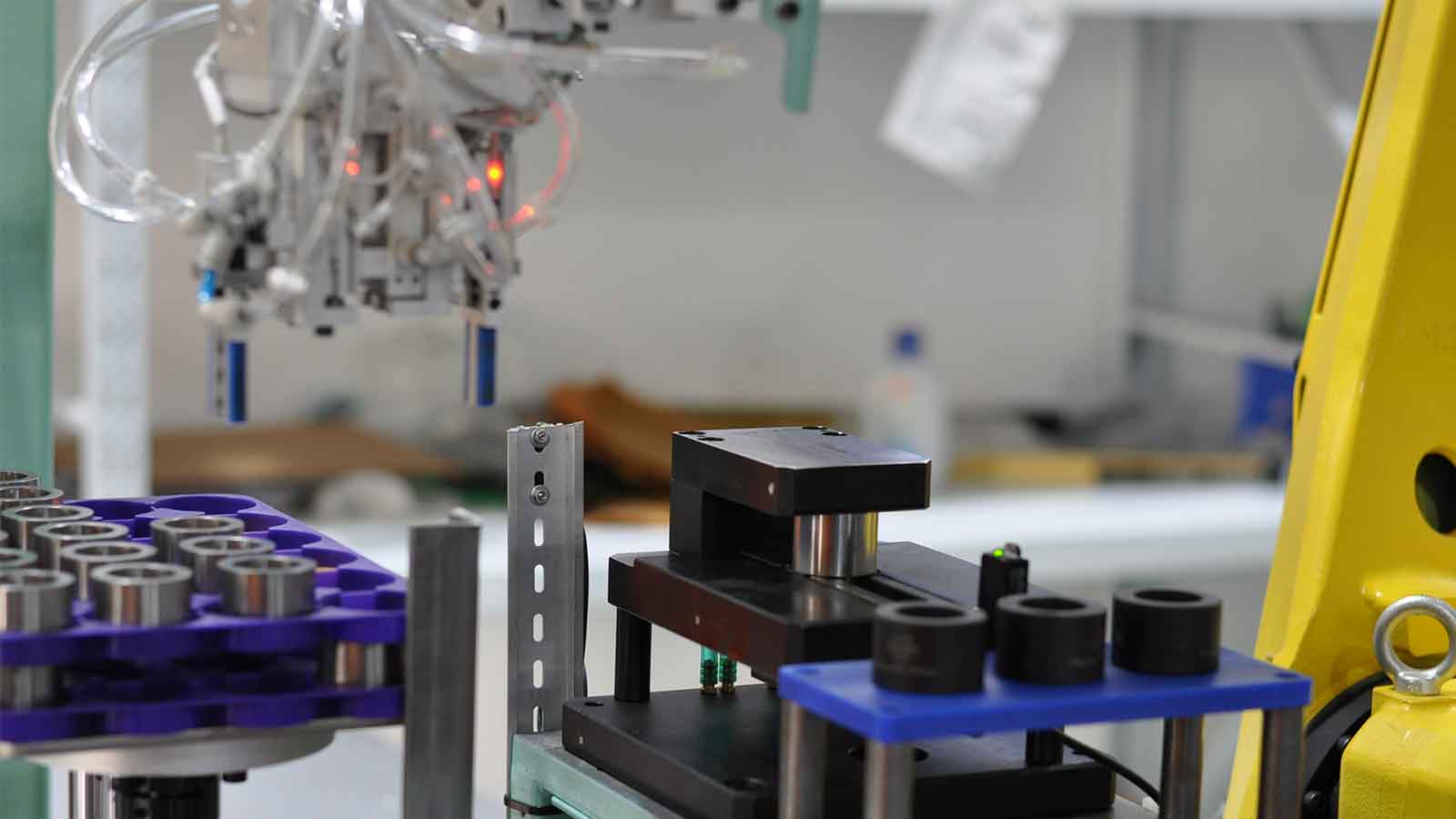

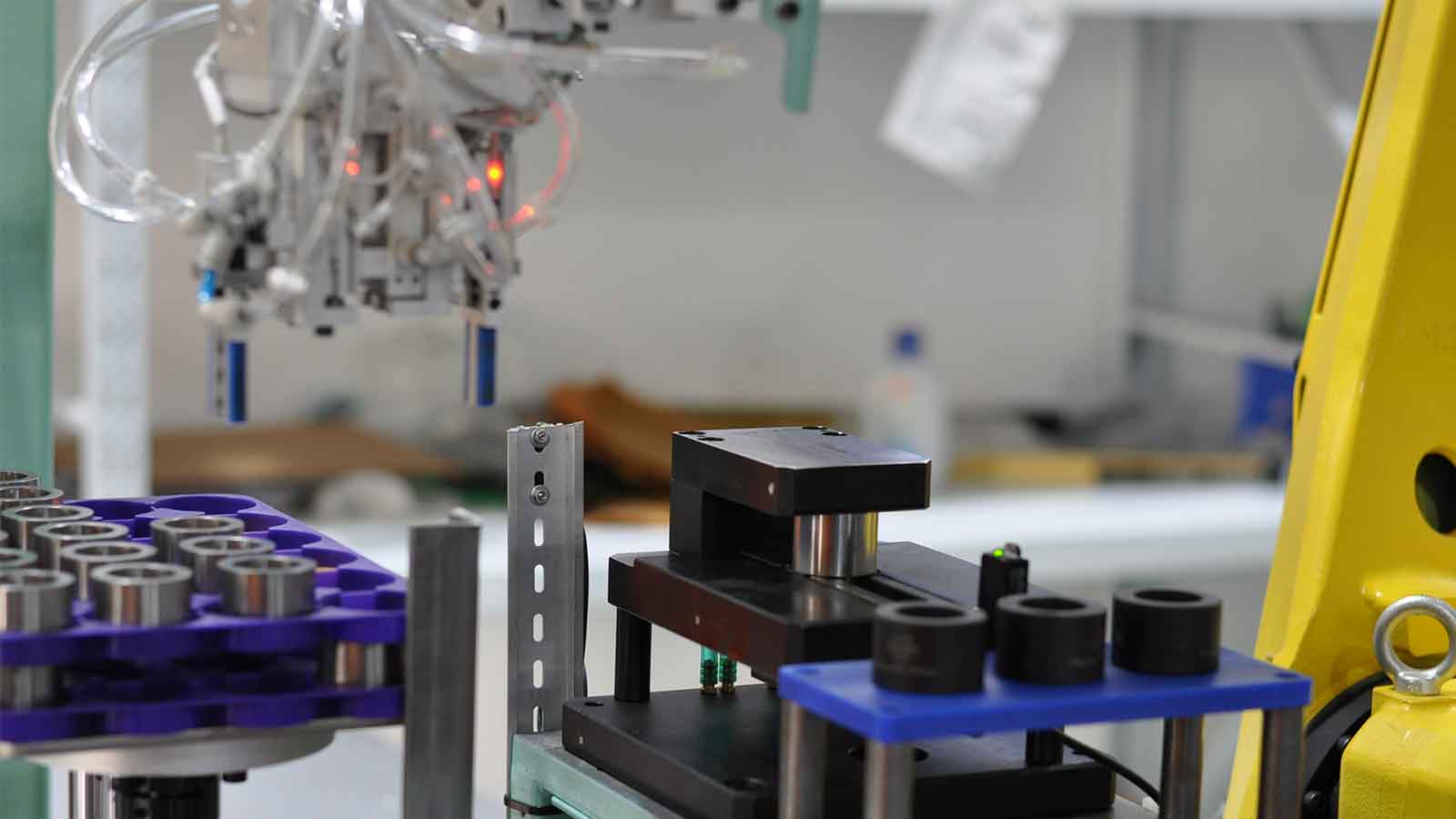

Yileride focuses on precision parts size pneumatic measurement, as a national high-tech enterprise and private science and technology enterprises in Jiangsu Province, has12Human technology research and development team, research and development personnel have participated in the United States Group, Gree, Mitsubishi, Panasonic and other companies of automatic measuring machine research and development, the company's annual research and development investment200Million, research and development of new products is not less than15If you are interested in precision parts dimension measurement or want to know more details, please click on our online customer service for consultation, or call the national unified service hotline directly

400-682-7787. We look forward to your call!