After the gauge is used, the following five points can extend its service life:

First, do not keep the working surface of the two gauges together (such as the plug gauge and the ring gauge set together), otherwise the two working surfaces will be glued to each other, and the external force will be unnecessary damage when separated.

Second, after the gauge is used, it should be cleaned with clean cotton yarn or soft cloth, put in a special wooden box, and then stored in the tool cabinet; Sheet gauges can also be hung in a tool cabinet. If the weather is humid or can not be used for a while, wipe clean and then apply a layer of acid-free petroleum jelly or anti-rust oil. The place where the gauge is kept must be dry.

Third, the gauge should be checked regularly, the general inspection cycle is6-12A month.

Fourth, whether the gauge is often used or not often used, it should be regularly inspected to see whether there is damage, rust or deformation. If it is found that the gauge begins to rust, it should be put into the gasoline in time for a period of time, and then carefully wiped out, and coated with anti-rust oil.

5. During use, the gauge should be placed in a stable place, such as the table of the tool cabinet or the wooden cushion plate of the stationary part of the machine tool, and should not be placed on the tool holder or the guide rail of the machine tool to avoid damage.

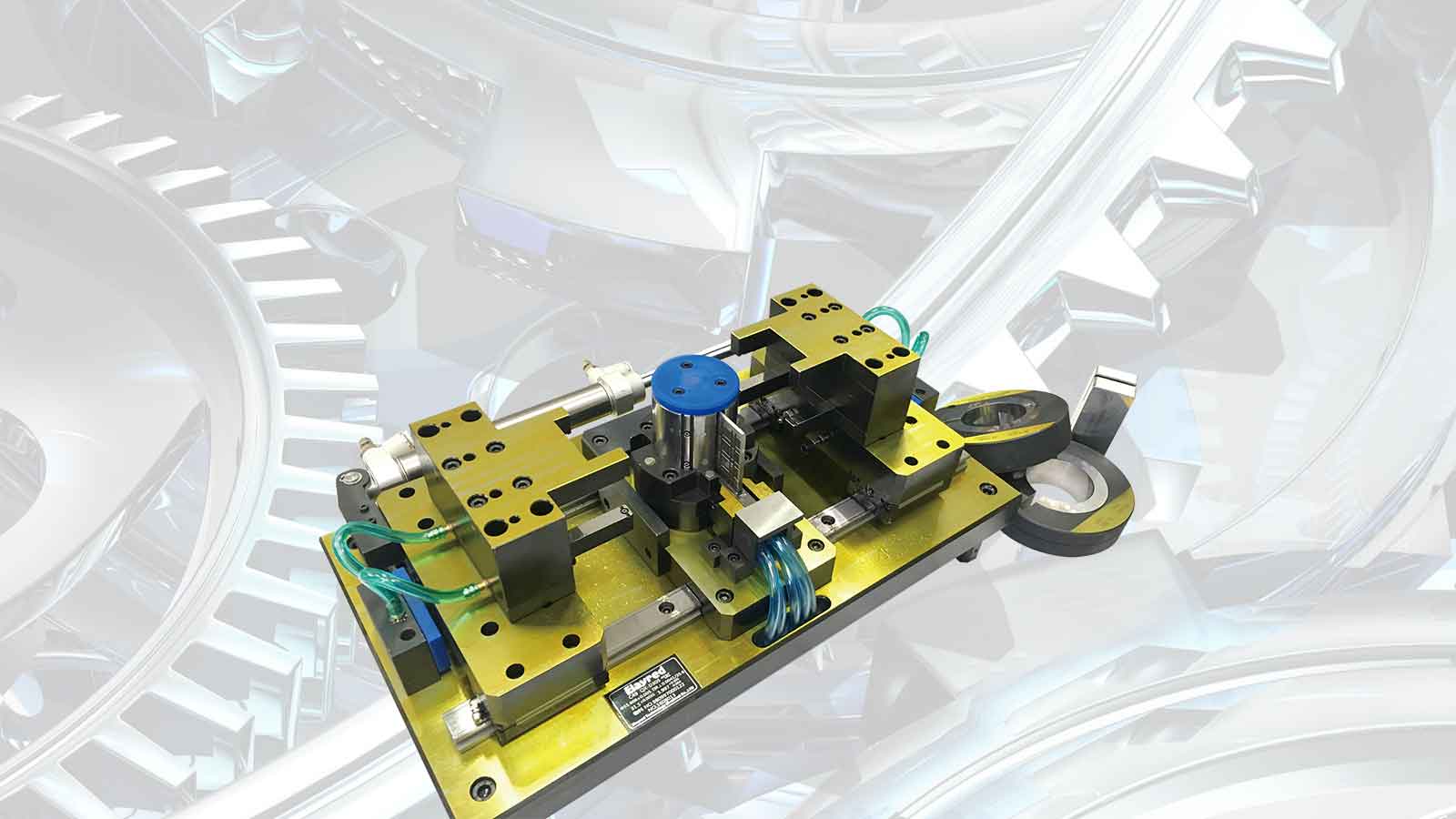

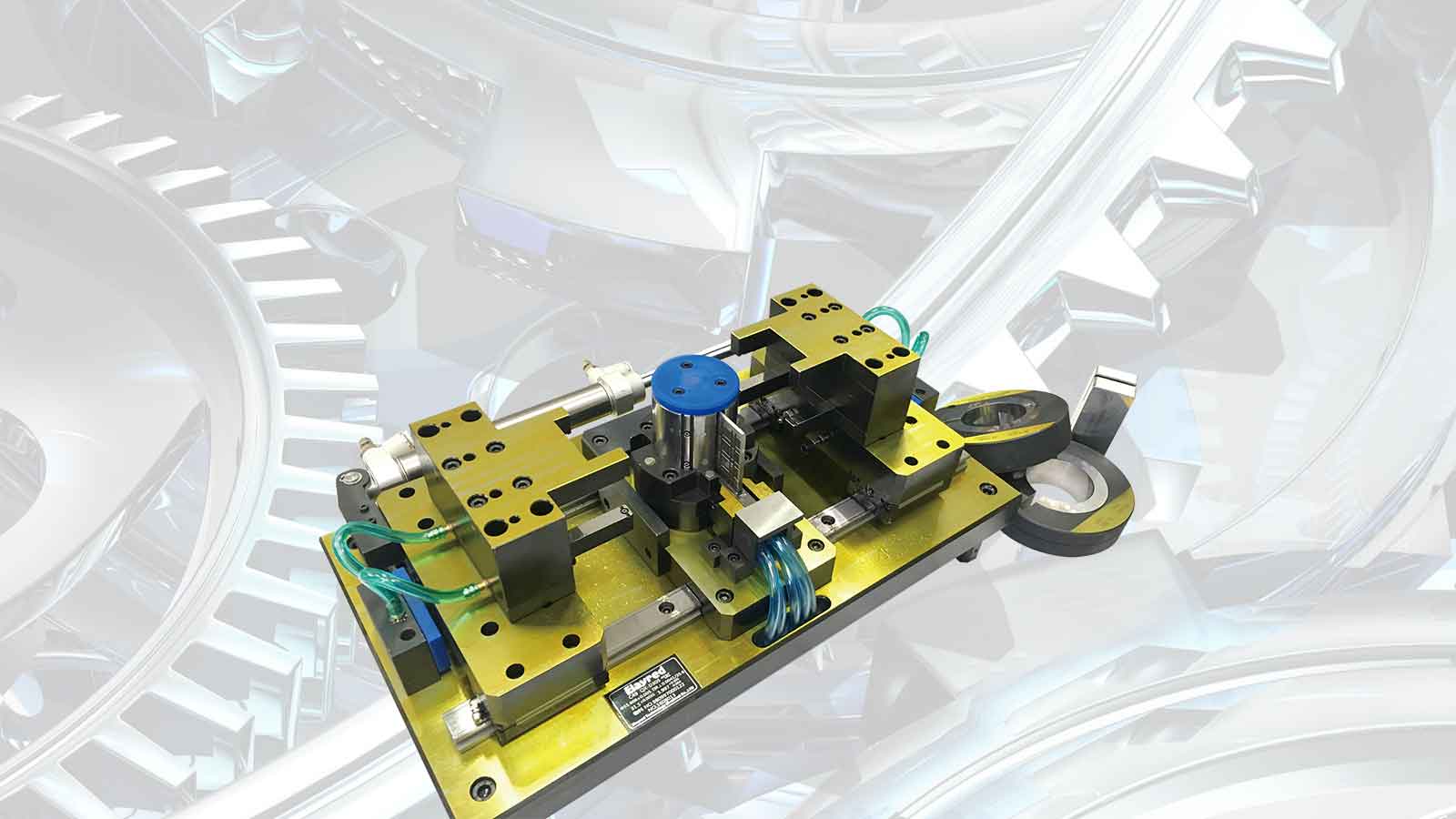

We focus on micro precision, is a professional precision parts size pneumatic measurement equipment manufacturer, if you

Billion lerideInterested, welcome to click on our online customer service for consultation, or directly call the national unified service hotline

400-682-7787. We look forward to your call!