The pneumatic probe realizes the sensing function of dimensional measurement, and the upper and lower standard parts provide the measurement reference. Before leaving the factory, the manufacturer will go through a series of processing processes such as heat treatment, mechanical processing, measurement, etc., to ensure the measurement accuracy and the requirements of dimensional tolerances with gas calibration, and pay attention to ensure the effectiveness and stability of the measurement when using gas calibration. Pneumatic measurement is based on the principle of measuring the size of the gap between the gas probe and the measured workpiece, and the general range of the gap is6μm-20μmFollow certain rules.

Model:E-MA4; Measuring range:±25μm,±50μm; Resolution:0.1/0.2/0.5/1.0; Total error:2%; Number of channels:Single; Measuring function:MXMNMNIAN-AMIN2

Model:E-MC5; Measuring range:±25μm,±50μm; Resolution:0.1/0.2/0.5/1.0; Total error:≤0.3μm; Number of channels:Single; Measuring function:MXMNMNIAN-AMIN2

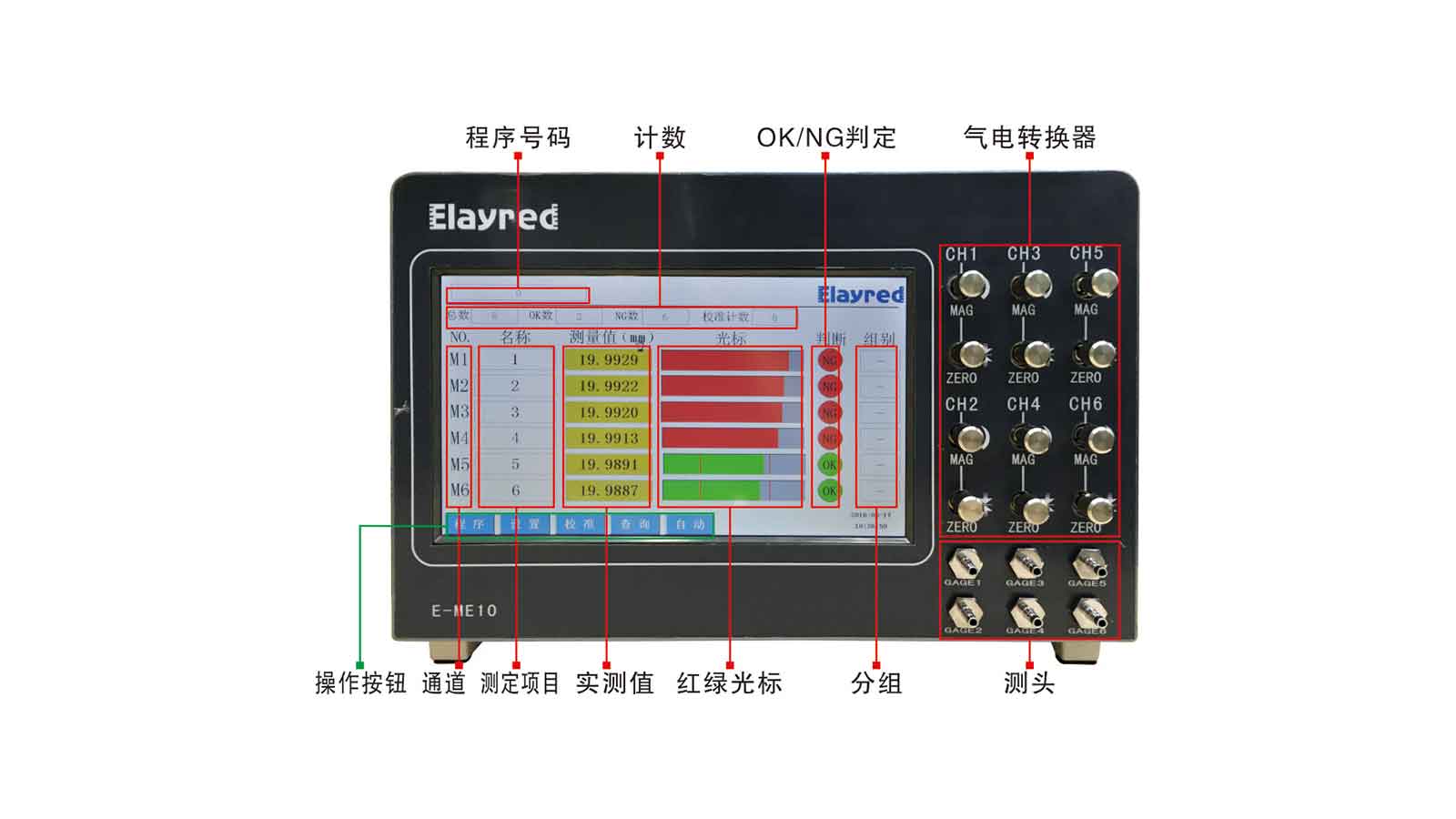

Display screen:7Inch; A/E:EA-2; Accuracy:≤0.3μm Resolution:0.1/0.2/0.5/1.0 Unit:μm/mm/inch