The pneumatic gauge can measure the inner diameter with micrometer accuracy. Its measurement principle is comparative measurement.

Because the gas gauge uses gas as the measuring medium, this measuring method has the characteristics of non-contact measurement. In addition, the gas meter is more sensitive to the cleanliness of the gas path, temperature and humidity, etc., and needs to be calibrated regularly during the measurement process. The system is fitted with a standard ring gauge at the measuring station for each test during actual use200Each product is calibrated once. At the same time, in order to solve the problem of the influence of the taper inside the product, each product is measured once in three different inner hole heights during the measurement process to make a comprehensive judgment. Pneumatic measuring instrumentADThe conversion program is loaded inPLCOn the system, with the system of electric, pneumatic, sensorsIOEqual sharePLCThe measured value passesRS-485Bus transmission to the vision system usedPCSystem to perform overall statistical analysis of the data.

Model:E-MA4; Measuring range:±25μm,±50μm; Resolution:0.1/0.2/0.5/1.0; Total error:2%; Number of channels:Single; Measuring function:MXMNMNIAN-AMIN2

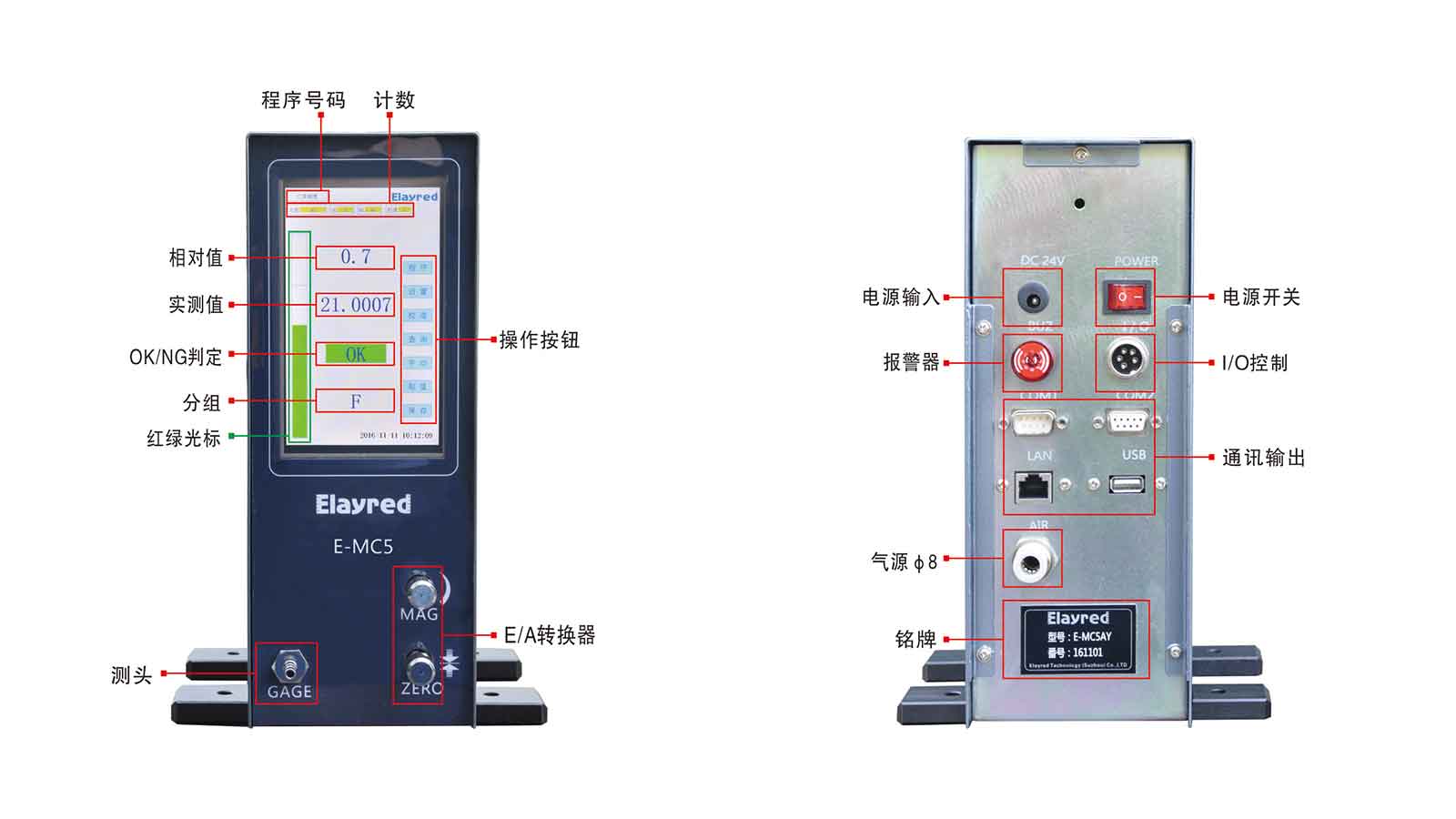

Model:E-MC5; Measuring range:±25μm,±50μm; Resolution:0.1/0.2/0.5/1.0; Total error:≤0.3μm; Number of channels:Single; Measuring function:MXMNMNIAN-AMIN2

Display screen:7Inch; A/E:EA-2; Accuracy:≤0.3μm Resolution:0.1/0.2/0.5/1.0 Unit:μm/mm/inch