Nowadays, there are many ways to measure the size of a workpiece, and many measuring instruments can be used, and many people do not know how to choose. In fact, to choose a meter that suits your needs, you first need to determine the functional requirements of your measuring task, and then choose a meter that can meet these rigid requirements. Here, billion leride roughly lists the various factors that need to be considered in the selection of measuring instruments, you can refer to:

Nowadays, there are many ways to measure the size of a workpiece, and many measuring instruments can be used, and many people do not know how to choose. In fact, to choose a meter that suits your needs, you first need to determine the functional requirements of your measuring task, and then choose a meter that can meet these rigid requirements. Here, billion leride roughly lists the various factors that need to be considered in the selection of measuring instruments, you can refer to:

1Characteristics and types of the workpiece to be measured:Is it flat, round, or some other type? Should I measure the inside diameter or the outside diameter? Is the location easy to reach? Is it next to a boss, a hole, or a narrow slot?

2, accuracy:There should be a reasonable relationship between workpiece tolerances and gauge resolution accuracy and repeatability (usually10:1), StatisticsGR&RTest need20:1Are the accuracy of your measuring instrument appropriate to the tolerances of the workpiece you are measuring?

3Test fee:As the accuracy of the measuring instrument increases, the cost will increase dramatically. In order to approach tolerances, before setting up measurement operations, you need to verify whether it is necessary for you to choose a high-cost measuring instrument.

4Time and capacity:Are fixed, dedicated gauges more economical than flexible, multipurpose ones? Is your production capacity batch or multiple individual pieces? Which measuring instrument can really help you save measuring time during the production cycle?

5Easy to use, easy to get started:Especially for gauges in factories, you should reduce the skill requirements of inspectors and the possible influence of inspectors.

6Maintenance costs:Meter maintenance or throw away? How often is it serviced? Who will maintain it? After a long period of operation, the accuracy will be lost, and you need to take some measures to ensure the accuracy.

7Cleaning of parts:Are the parts dirty or clean during your measurement? This may affect the experimental conditions, accuracy and level of maintenance. Will the selected measuring instrument work in your measuring environment? Or do you use a gas gauge? becauseThe air gauge has self-cleaning function.

8Measurement environment:The measuring instrument is susceptible to dust, vibration, temperature changes, will the measuring instrument you choose be affected by these?

9, mobility:Do you move the workpiece or the measuring tool when you measure?

10, workpiece processing:What happens after the parts are inspected? Are unqualified parts scrapped or reversed? Is there a set of requirements?

11, tool materials and finishing quality:Can parts be compressed? Is it easy to scratch? Many standard gauges can be modified to avoid these effects.

12Manufacturing process:If a machine or tool squeezes the finished surface of a part once, the part will become irregular. Will you take this into account when choosing a measuring instrument?

13, expenses:What is the price of the measuring instrument of your choice? What's your budget?

When you embark on an inspection task and need to confirm what kind of measuring tool to choose, all of the above factors are important, they can help you define as much as possible, narrow the scope of your choice, and facilitate the final choice.

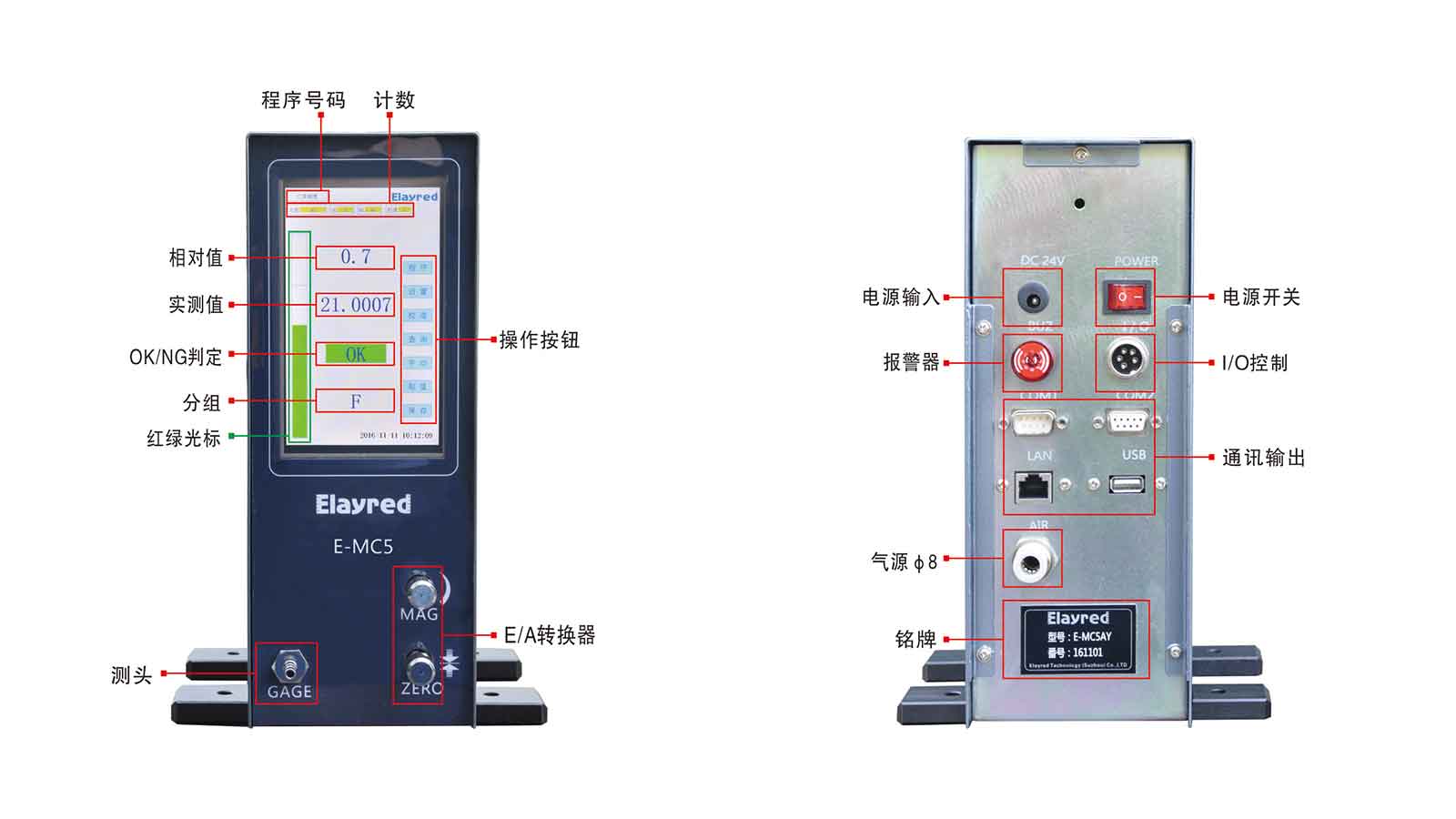

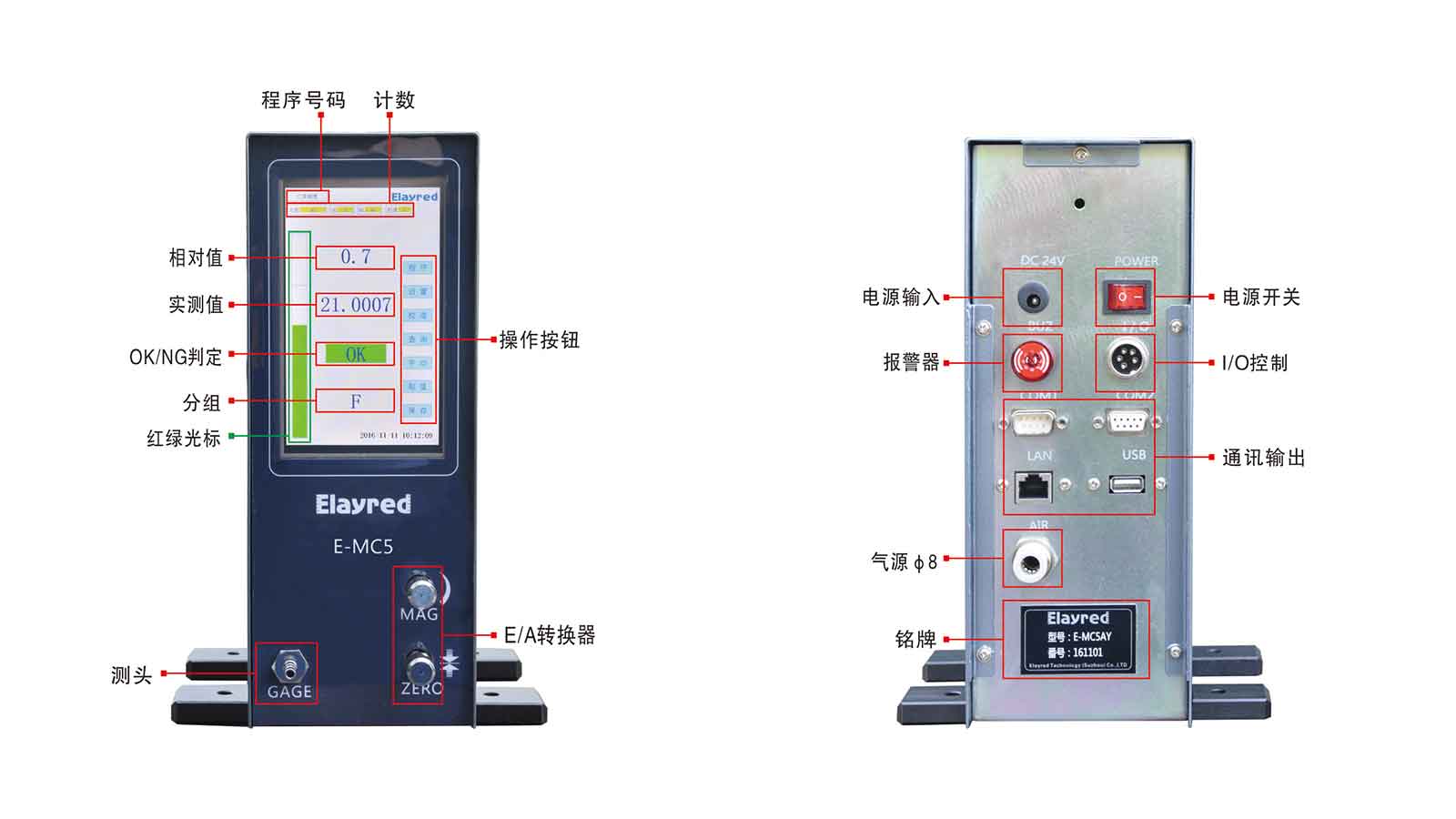

As a precision parts size pneumatic measurement equipment manufacturers, focusing on micro-precision, R & D and production of digital display pneumatic momentum meter, a variety of models, quality assurance, manufacturers direct sales, price concessions.

If you are

Digital display gas momentum meter Interested or want to know more details, please click on our online customer service for consultation, or directly call the national unified service hotline

400-682-7787. We look forward to hearing from you!