Pneumatic measurement has the following advantages:

1There are many measurement items, such as length, shape and position errors, etc., especially for some measurements that are difficult to be solved with mechanical measuring tools and measuring instruments, such as: the inner diameter of the sounding hole, the inner diameter of the small hole, the width of the narrow slot, etc., it is easier to achieve with pneumatic measurement.

2The magnification of the measuring instrument is high, and the human error is small, which will not affect the measurement accuracy; There is no mechanical friction during operation, so there is no return error.

3The operation method is simple, the reading is easy, the continuous measurement can be carried out, and it is easy to see whether the sizes are qualified.

4The measuring head is not in direct contact with the measured surface, reducing the impact of the measuring force on the measurement results, while avoiding scratching the surface of the measured part, especially for the measurement of thin-walled parts and soft metal parts.

5Due to non-contact measurement, the measuring head can reduce wear and extend the service life. A hose connection is adopted between the main body of the gas gauge and the measuring head to realize remote measurement.

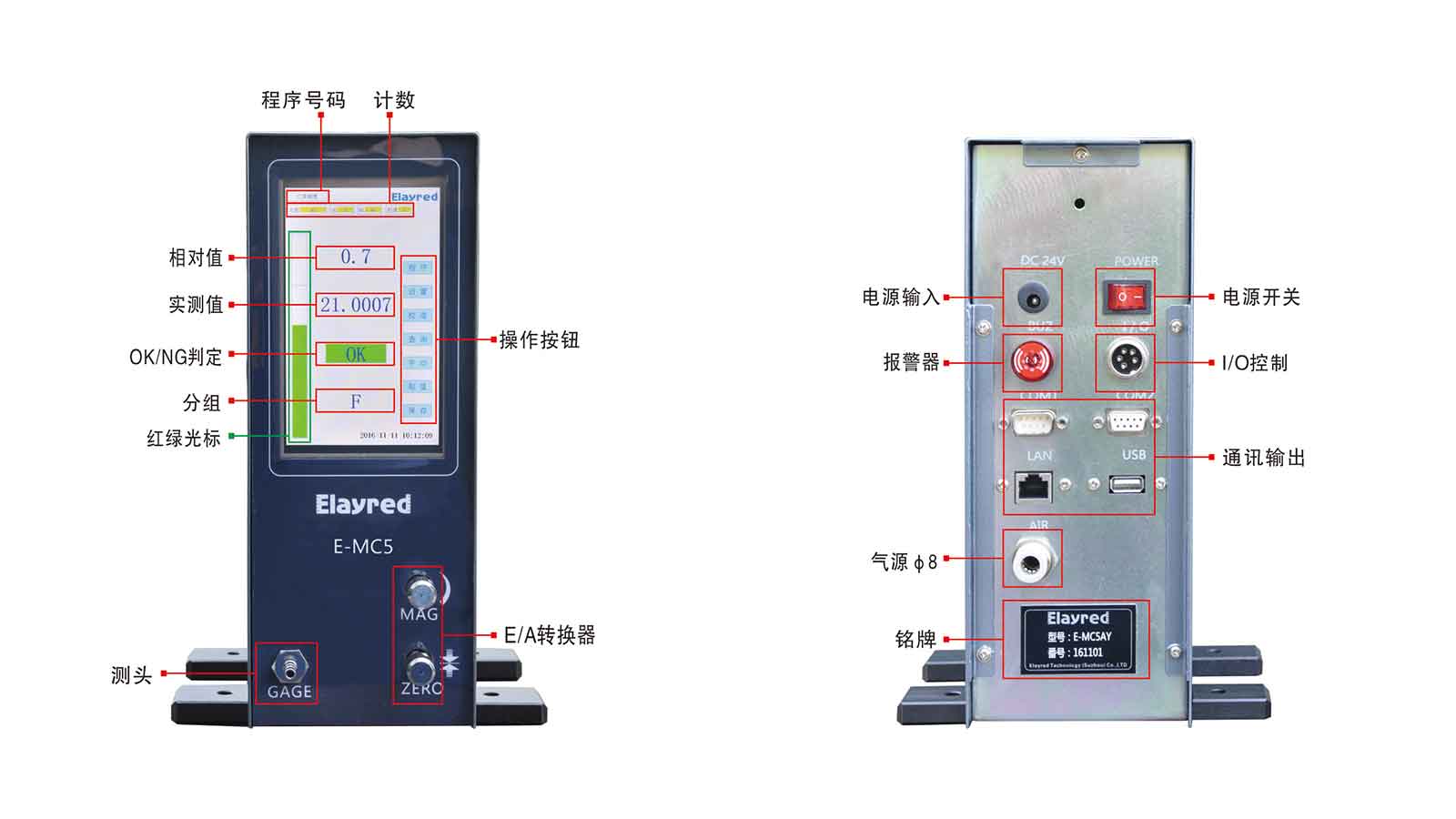

As a precision parts size pneumatic measurement equipment manufacturers, focusing on micro-precision, R & D and production of digital display pneumatic momentum meter, a variety of models, quality assurance, manufacturers direct sales, price concessions.

If you are

Digital display gas momentum meter Interested or want to know more details, please click on our online customer service for consultation, or directly call the national unified service hotline

400-682-7787. We look forward to hearing from you!