No matter how complex any part is, it is made up of many elements. The research object of form and position tolerance is the elements, namely points, lines and surfaces. According to the feature classification, the elements can be divided into different types, the following by billion Leride for you to explain it!

No matter how complex any part is, it is made up of many elements.The research object of form and position tolerance is the elements, namely points, lines and surfaces. According to the feature classification, the elements can be divided into different types, the following isBillion lerideLet's explain it to you!

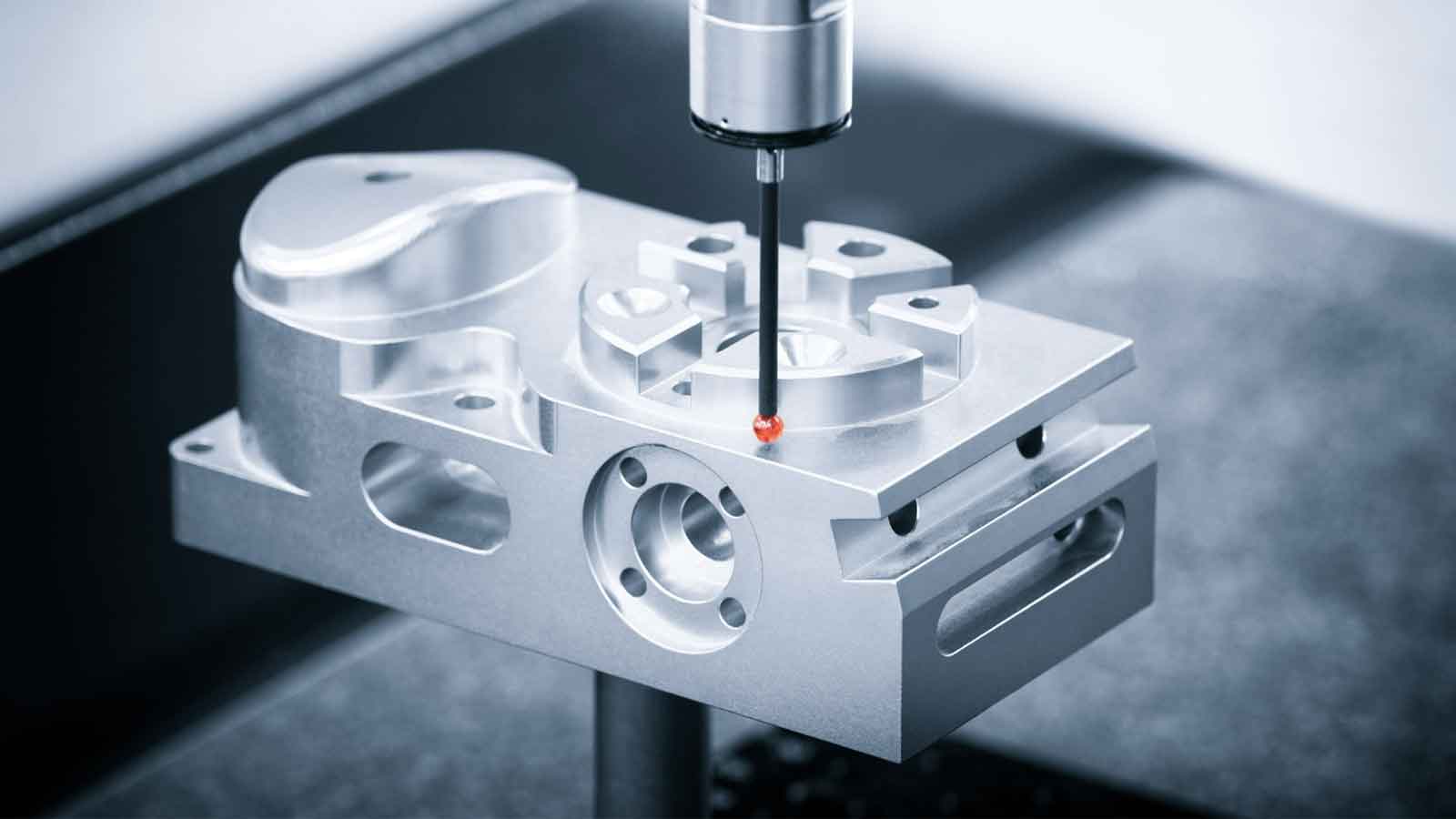

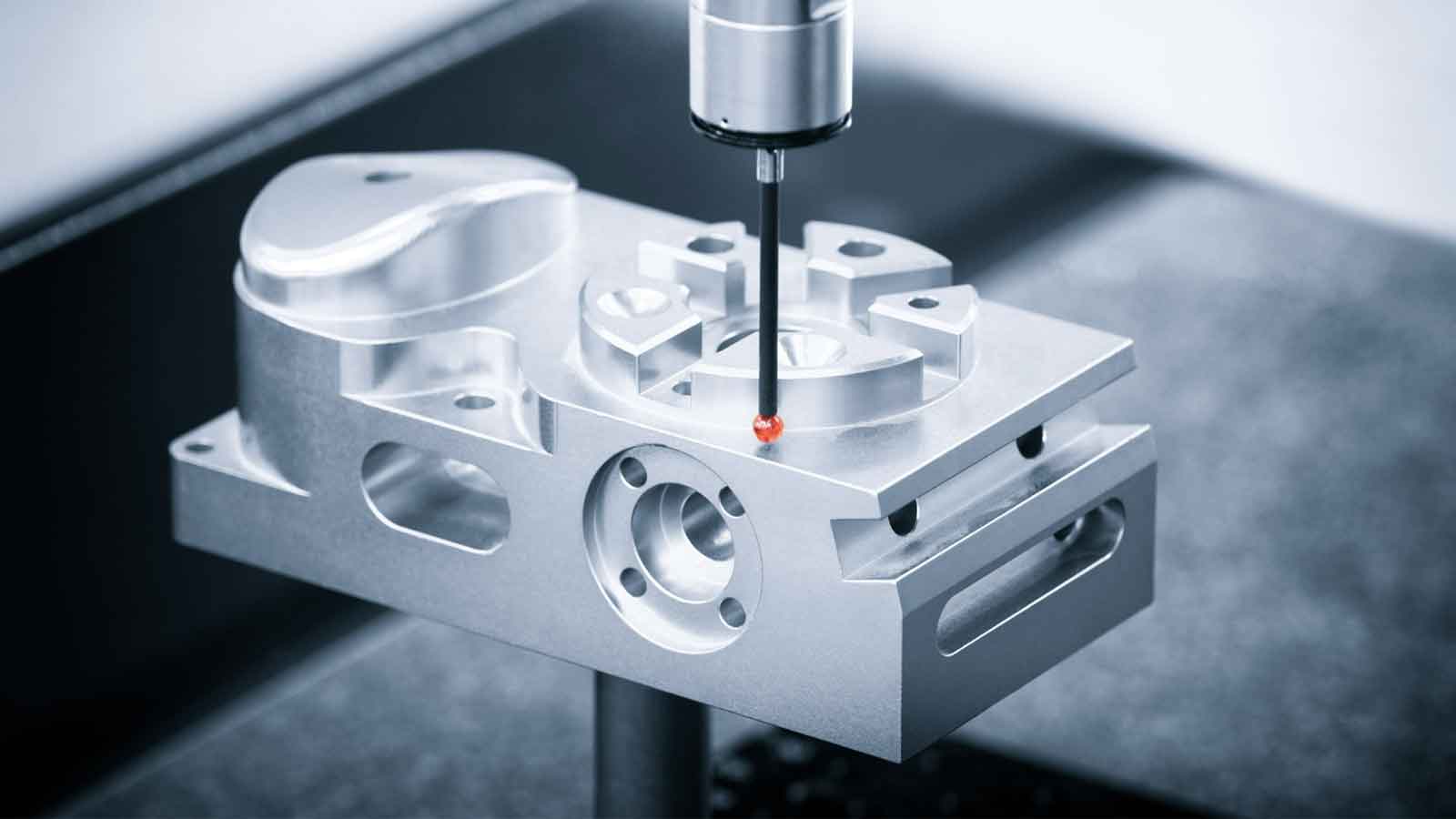

(Figure source network, intrusion)

1.According to the structural characteristics:

Outline (real) elements:A point, line, or surface on a surface.

Central (derived) elements:The center point (center of a circle or sphere), center line (axis), or center plane obtained by one or more contour elements.

2.According to the status:

Factors to be measured:The elements of the form and position tolerance requirements are given on the drawing and are the objects of measurement.

Benchmark elements:The actual elements on the part used to establish the benchmark and actually act as the benchmark(As an edge, a surface, or a hole).

It is worth noting that the measured elements are generally connected to the form and position tolerance boxes on the drawing through arrow guide lines; Reference elements are represented by reference symbols on the drawing, reference elements≠Benchmark.

3.According to the state of existence:

Actual elements:Elements that actually exist after parts are processed (errors exist).

The actual factor is embodied by the approximate substitute factor (measured actual factor) obtained by measuring a finite number of points on the actual factor according to the specified method; Because of the different measurement methods, each actual element can have several alternative elements. The smaller the measurement error, the closer the measured element is to the actual element.

Ideal elements:The correct elements of the theory (without error).

In technical drawing, the elements we draw are ideal elements; Ideal contour elements are represented by solid (visible) or dashed (invisible) lines; The ideal central element is represented by a dotted line.

4.According to the structure performance:

Single element:Elements with shape tolerance requirements.

Related elements:An element having a functional relationship with other elements.

Functional relationship refers to a certain direction and position relationship between elements, such as vertical and flat

Line, coaxial, symmetry, etc., that is, elements with position tolerance requirements.

5.According to the relationship with size:

Size elements:A geometric shape defined by linear or angular dimensions of a certain size.

The dimensional elements can be cylindrical, spherical, two parallel corresponding surfaces, conical or wedge.

Non-dimensional elements:No size size geometry.

Non-dimensional elements can be surfaces, plain lines.

Focusing on micro-precision, Eleride provides measuring equipment and technical services for home appliances (compressors), automotive, aerospace (aerospace), precision machining, semiconductor manufacturing and other industries. If you are

Billion lerideInterested or want to know more details, please click on our online customer service for consultation, or directly call the national unified service hotline

400-682-7787. We look forward to your call!